Belt is critical component of every cassette player. That’s why choosing correct belt for your cassette device is very important.

Belts can be used on various places of your cassette decks, for example main belt, inter-capstan belt, mode belt, counter belt… Some are square, some are flat. The most discussed belts are those that affect audio quality. Old good belt producers are gone forever and current belt producers cannot make belts of quality required by sensitive cassette deck mechanics.

These are three parameters that have to be taken into consideration, when choosing right belt:

Using incorrect belt will have negative effect to tape stability, wow/flutter, mechanics noise and parts wear. Each cassette transport is designed to use belt of specific parameters. It is always good to find balance between belt length, belt thickness and belt material. Some mechanics require elastic , some require harder belts. Some are more sensitive to correct belt, some less. It is given by design.

There is wide choice of generic belts of various lengths and types on today’s market. There are suppliers of generic belts, like ASWO here in Europe, or turntableneedles in US. They are very cheap, optically they look very good. The only problem is that their surface quality is not sufficient enough to meet specs given by manufacturers of cassette decks. Some transports, like Aiwa dual capstan transport, are very sensitive to belt quality.

Fortunately, quality of flat belts can be significantly improved using method of sanding. There can be several reasons why the belt is not perfect.

One of them is surface not smooth enough. It does not necessarily need to be visible by naked eye. You can feel it when you move your finger along the belt surface.

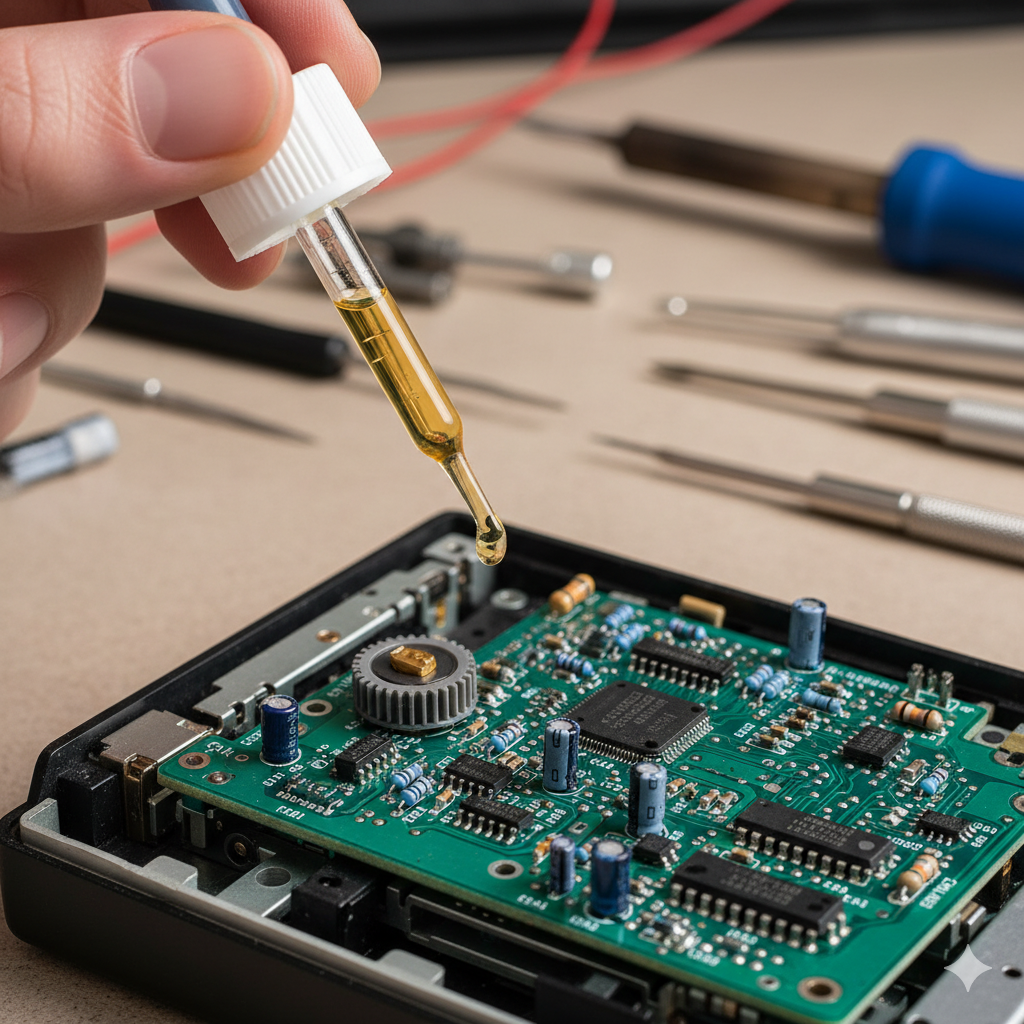

It is possible to use this DIY method using very cheap tools, at home environment. The only tools that you need is 600 grit sanding bands rotary tool. As a result, surface of such belt will be smooth, uniform and flat.

By using this method, I could reduce wow/flutter from 0.07% (10 sec peaks) WRMS to 0.03%, by just adjusting belt A of Aiwa XK-009 cassette deck. This method was tested in various cassette decks with similar results.

Warning! Not all belt materials are suitable for this modification. EPDM, NBR materials can be easily sanded. On the other hand, neoprene is very difficult to sand.

Another one is thickness inconsistency.

It means that the belt thickness varies around the belt length. Quality original belts vary less than 0.005 mm. In case of currently produced belts, it is a question of luck. When I ordered new belts of various dimensions from my manufacturer, in case of some dimensions, the belts are perfect while in case of some other dimensions they are very badly. Sometimes also quality varies within the same size. I measured some old Sony and Aiwa belts and thickness uniformity was always within 0.002 mm. In case of new belts, I never found better than 0.008 mm. 0.01 to 0.015 is typical. And some belts from crap producers vary within 0,2 mm! So what can we do to improve it? It is not difficult but it requires patience and a time. And you will need the sanding rotary tool described above plus quality micrometer with constant push force.

I use to measure belt thickness cm by cm and I mark place where the thickness is largest. I repeat measurement to confirm it.

Then, I use the sanding tool to adjust thickness around the marked place. I move up and down the rotary tool, around the marked place.

Then I repeat the whole process again until I find another maximum thickness. I repeat the steps until thickness varies within 0.005 mm range.

It need a little practice but result can be very good.