Cassette decks, personal cassette players, and boomboxes use delicate and complex mechanisms with many moving parts such as levers, gears, capstans, idlers, and motors. For trouble-free and accurate operation with minimal wow and flutter, all of these components must move smoothly. To reduce wear and ensure long-term reliability, proper lubrication is essential.

In cassette transports, two types of lubricants are typically used:

Grease

Oil

Grease is used for slow-moving parts such as levers, cam gears, and door mechanisms. It is crucial to choose a grease that is compatible with the materials it will contact. The grease must not accelerate aging of plastics or metals and should remain stable over time. Old or unsuitable grease can harden into a sticky residue, potentially damaging the mechanism during normal use.

At fixyouraudio, we recommend Japanese Molykote EM-30L. It is safe for both plastic (POM) and metal components, and it provides long-lasting lubrication without degrading.

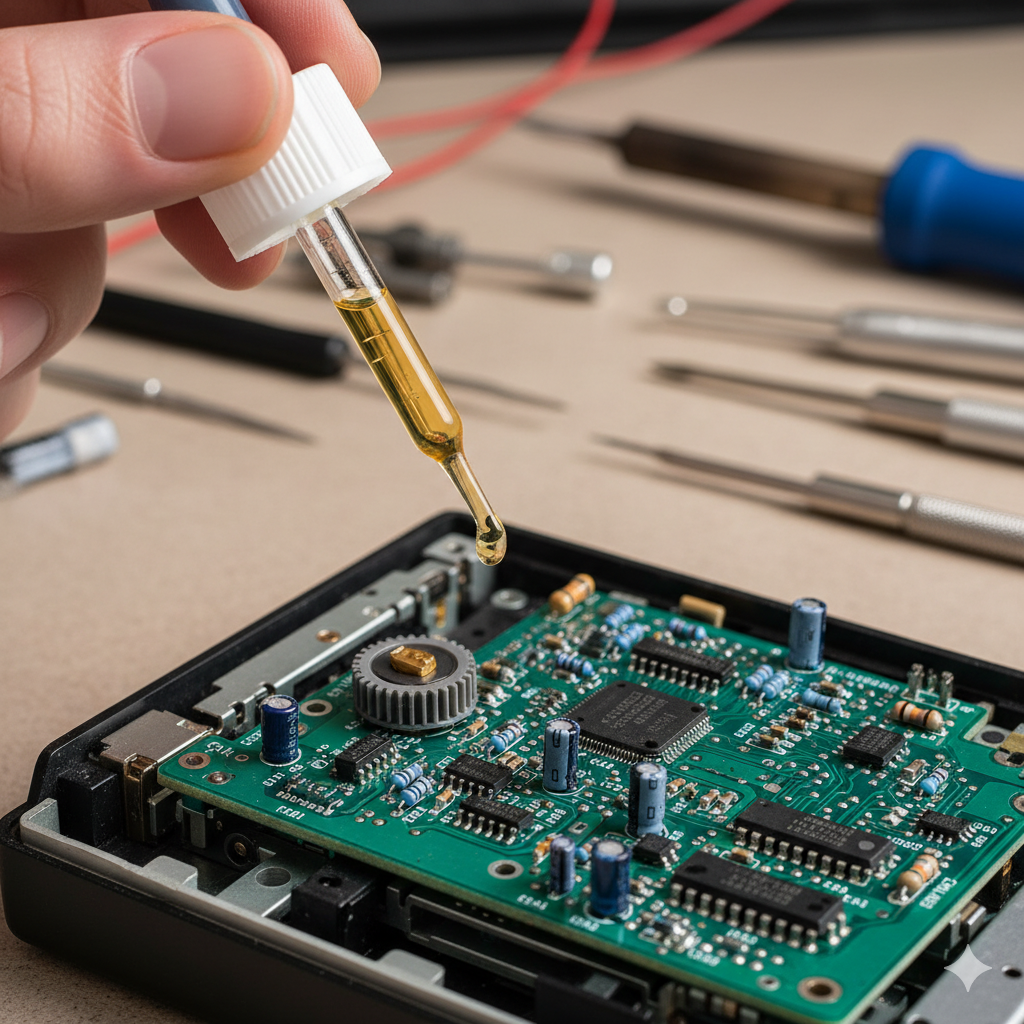

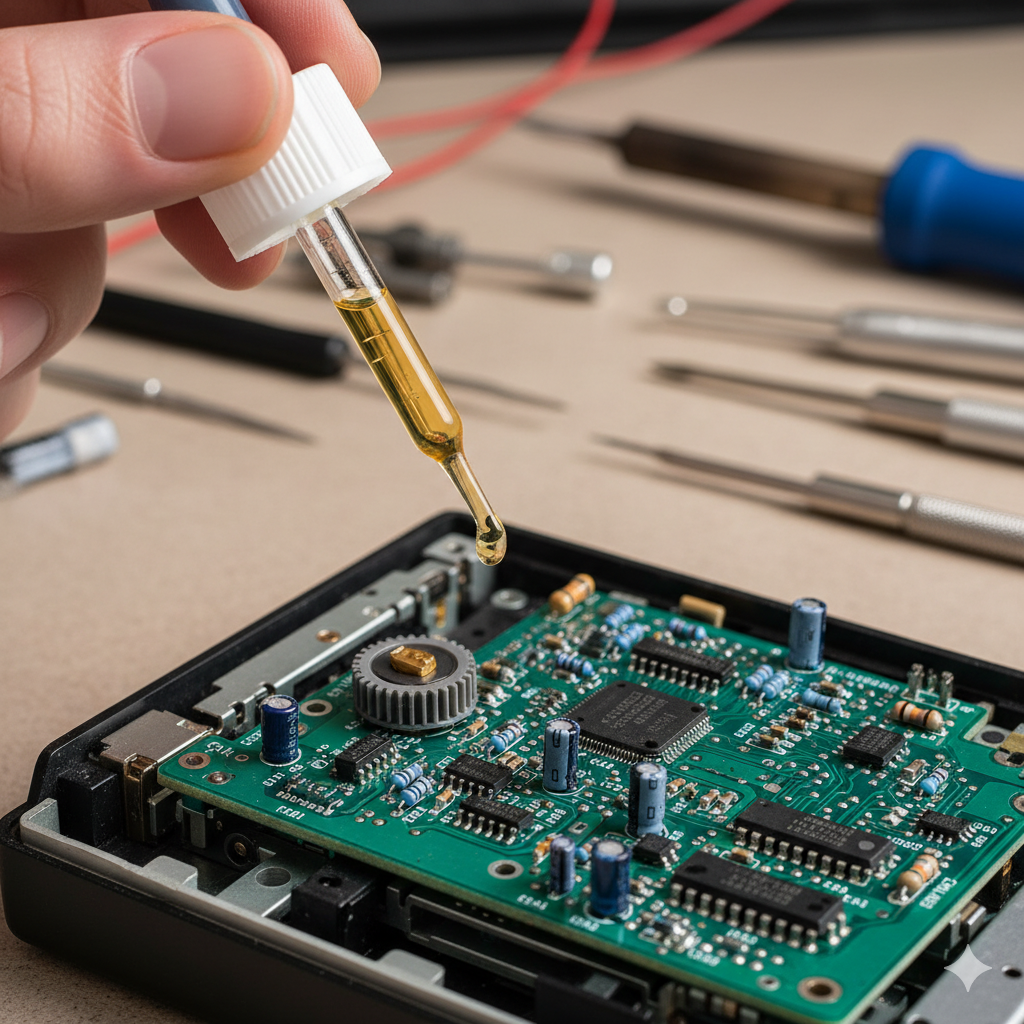

Oil is used for lubricating rotating parts, including capstans, motor shafts, and other precision components. The most critical applications are the sintered bronze bearings of capstans and motors. Only a high-quality oil specifically formulated for sintered bearings should be used.

Ordinary oil is unsuitable—it will age poorly, dry out within a few years, and turn into a sticky glue-like substance. This not only damages the bearings but can also make disassembly impossible. For this reason, only specialized oils such as Klüber Isoflex PDP-65, developed for precision bearings, should be used.

Some online sources recommend motor oil for capstan bearings. This must be strictly avoided. While motor oil may initially reduce vibration and lower wow/flutter due to its density, within one or two years it will clog the pores of the sintered bronze, causing irreversible damage. Proper specialty oil is therefore the only safe choice.

Do not lubricate plastic gears.

They are usually made of POM, a material with excellent low-friction properties. The only exception is slowly moving gears, such as those used in door-opening mechanisms, which may benefit from a small amount of grease.

Lubricating sintered bronze bearings

Apply a few drops of oil inside the bearing, then gently heat it to about 80 °C for a few minutes to allow the oil to penetrate. Repeat this process if necessary. Be careful not to overheat, as excessive heat can damage nearby plastic parts.