Screwdrivers are inexpensive tools, yet they are absolutely essential for any type of repair work. In this article, we will guide you in selecting the right screwdriver and share some practical tips for using them correctly.

Most personal cassette players and Walkmans use M1.4 screws of various lengths, typically with a cross-shaped Phillips PH00 head. Some lower-cost plastic models may instead use PH0 or PZ0 screws. Larger cassette decks generally use Phillips screws in sizes PH0 to PH2. In rare cases, flathead or Torx screws may also be found.

Using a screwdriver with an incorrect or undersized tip will almost certainly damage the screw head. Choosing the correct size and shape is therefore essential.

The quality of the screwdriver is just as important as selecting the correct size. A poorly manufactured or imprecise tip will quickly strip screw heads. Likewise, if the tip is made of soft material, it will wear down rapidly and in turn damage the screws.

At fixyouraudio, we have been using a single Japanese Vessel screwdriver for over 20 years—the tip is still like new. It is far better to invest a few extra euros in one high-quality screwdriver than to replace many cheap ones. A good screwdriver will also hold the screw firmly on the tip, making work easier.

Avoid purchasing from untrusted sellers or unknown online shops. A “too cheap” Japanese screwdriver is almost always a counterfeit. On fixyouraudio, you can find some of our recommended models, which we import directly from Vessel.

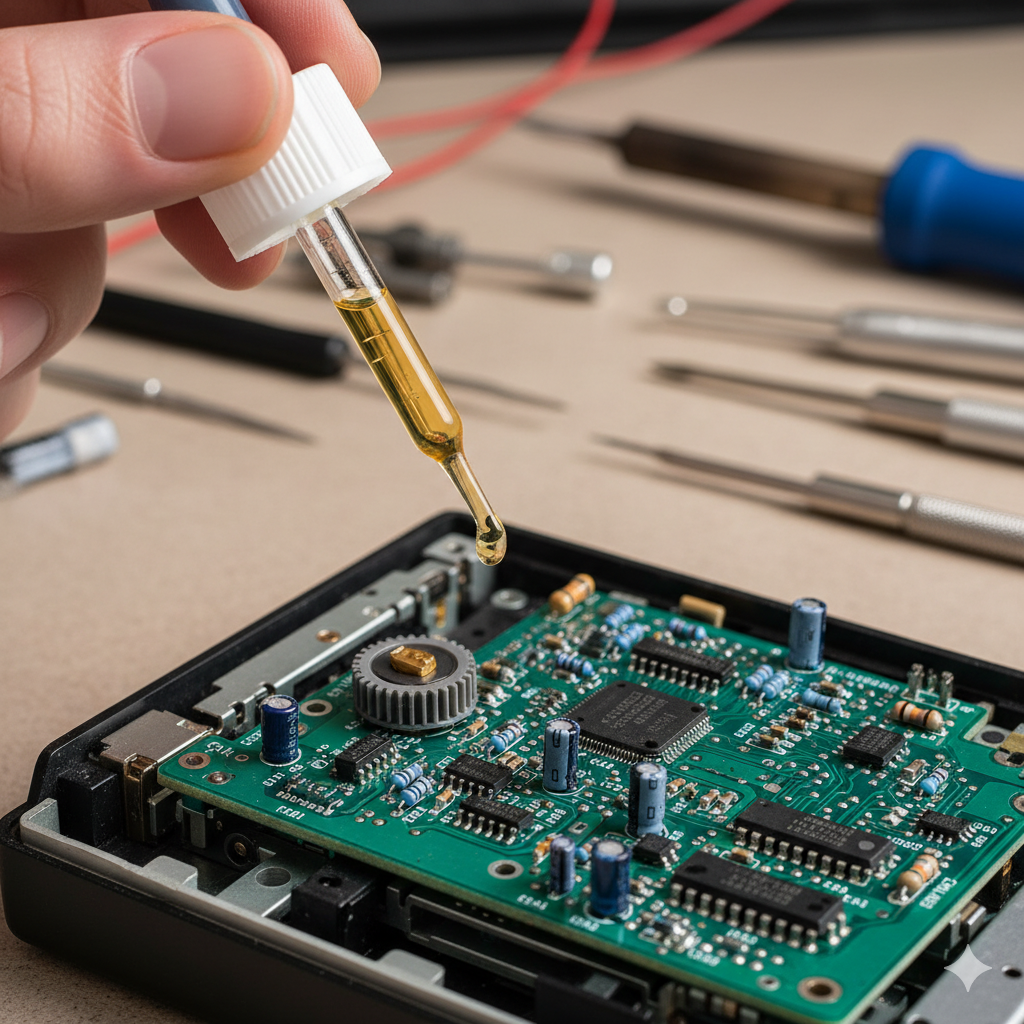

For delicate operations such as head height or azimuth adjustments, always use a special non-magnetic screwdriver with a ceramic tip. Similarly, for electrical trimmer adjustments or motor speed calibration, a ceramic non-conductive flathead screwdriver is recommended.

If a screw is stuck and cannot be removed easily, press the screwdriver firmly into the screw head while slowly turning counterclockwise. Applying strong downward pressure is critical—and it is equally important to use a high-quality screwdriver. A good tool allows you to apply strong torque without damaging the screw head, something impossible with cheap screwdrivers.

Also, remember to support the component from the underside; otherwise, the downward force may bend or damage it.